SBS 2 Side Coated

The SBS 2 Side Coated bleaching process involves applying a layer of white pigment to both surfaces of the cardboard. So this pigment is applied using a special machine that applies the pigment evenly across the entire surface of the board. Once the pigment is applied, the cardboard is heated to dry the pigment and create a smooth finish on both sides.

-

As far as an optimal surface for high-quality printing

-

as well as stiff material with a glossy surface on both sides

-

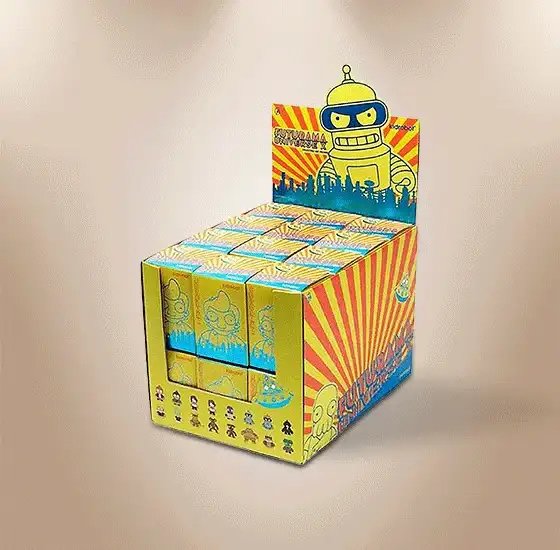

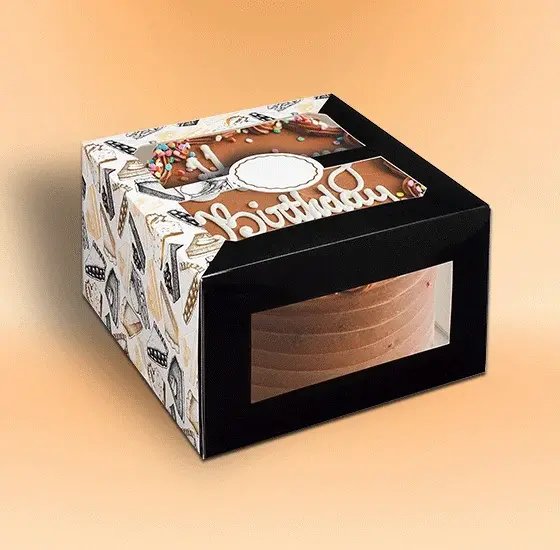

Especially best to use as wrapping paper for rigid boxes

We offer a range of materials and special finishes which you can use to create custom boxes that suit your brand. From the hardwearing corrugated cardboard, to the rustic kraft paper or cardstock as an alternative, we have options for each product you make. For an elegant touch, we have various special finishes including matte or glossy lamination, embossing or debossing for additional textures and foil stamping for luxurious look while spot UV coating will emphasize on some specific elements. With die-cutting facilities in place, one has even greater freedom of creating unique presentations through making custom shapes and windows. Our customized packaging options will take your brand to the next level and ensure it remains unforgettable.

The solid bleached sulfate (SBS) board is white cardboard used in the packaging boxes. It is manufactured using wood pulp and bleached sulfate process. SBS C2s is a two-sided coated version of SBS. It’s designed to make your print job look better and last longer. This coating helps keep the ink on the paper so it doesn’t run off when you use the package. Also this makes it a great choice for packaging because it’s recyclable and biodegradable, and both sides can be used for printing. It’s also odorless and tasteless, which makes it perfect for packaging food, cosmetics, and pharmaceutical products. Certainly it’s strong enough to withstand heavy loads and high temperatures, so it’s a great choice for shipping and storage boxes.

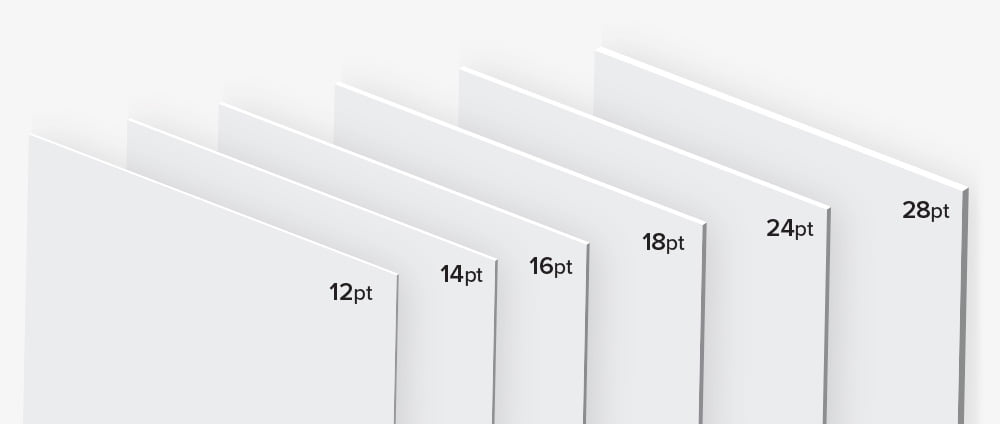

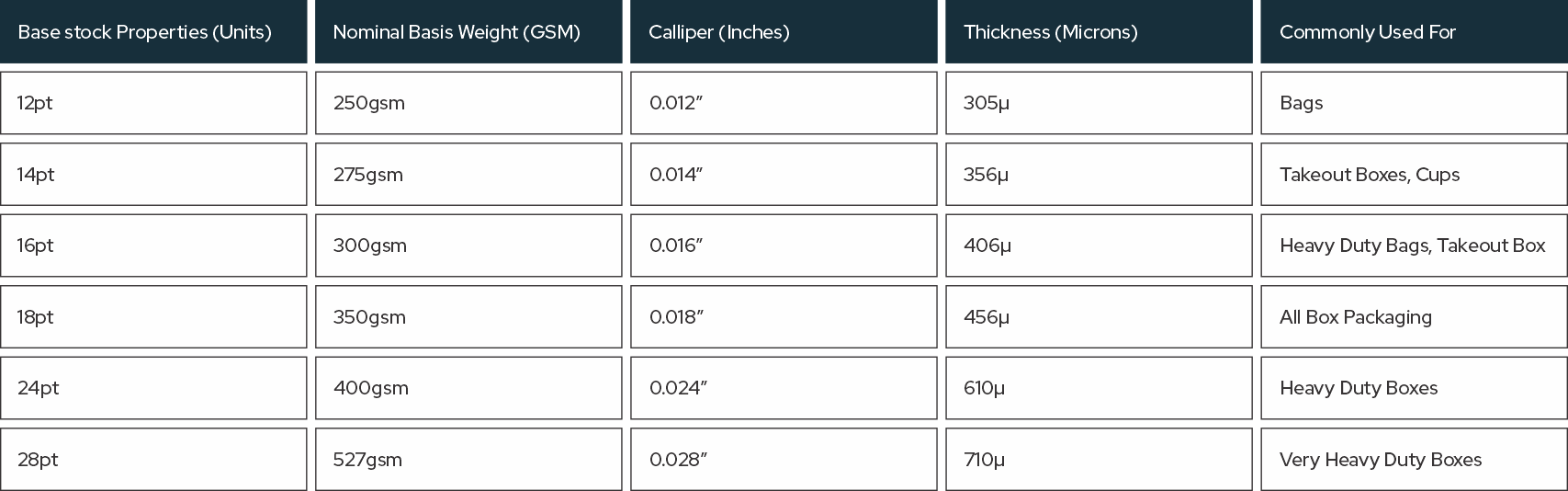

Conversion Table for Paperboard Thickness and Grammage

Cardboard Thickness